A common failure for the small LCD displays found in electronics – missing lines.

Are you stuck with a bad LCD that has missing lines? It is not easy finding replacement LCDs for most situations because a lot of them are custom made for a single device and just not available separately. Also the driver ICs quickly become obsolete as manufacturers find better way to do things like faster response, lower power usage or more features, etc.. so it may not even be possible to duplicate the LCD even after as little as 3 years.

If you have an LCD you would like to try to repair, maybe this information will help you accomplish your goal.

There are several ways of connecting the circuit board to the glass. The two most common are by a zebra connector (a rubber conductive strip held by pressure between the glass and the PCB) or by using a heat seal flexible conductor strip. The second is what I will be covering here. The heat seal is prone to problems late in life. As the connector dries up and exposed to alternating temperature it can lose conductivity in some of the contacts… and that causes the missing lines shown in the pictures here.

The heat seals have conductive adhesive holding them in position. They are assembled using a complicated heat sealing machine that is out of reach for even the most technically equipped of us. It is however possible to repair them with common equipment and supplies. 🙂

The first thing you need to know is the problem is almost always (more than 99% of the time) on the PCB side of the connector. The glass side hardly ever has a problem.

Now to repair your defective LCD, all you need to do is heat up that strip while applying pressure. Easy! Or is it??

The temperature required varies a bit and needs to be up there around 300 F or more. It’s unlikely you will have access to tools that can both apply heat and pressure at precise temperatures but the good news is I’ve found they are not too picky about too much heat (within reason)

Heating with a heat gun and then applying pressure does not seem to work. The good news is, a tool that can work is just as easy to come by…. it’s a soldering iron! Now you cannot just start jabbing the heat seal with a soldering iron set to melt solder. The temperature has to be lower or you will instantly melt the plasticky/paper conductor strip. Also the hard metal pointy tip isn’t the best.

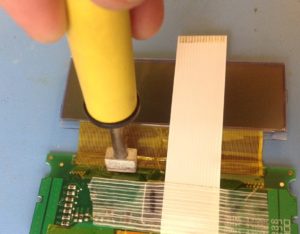

What I have found success with is using a large soldering iron tip on a soldering iron set at a very low temperature (400 F is a good start) with a thin silicone pad between the iron and the heat seal. I cut a strip off a transparent silicone rubber keypad from a telephone dial pad.

It does take some practice and you need to be careful. It’s easy to slip off the pad and touch the fragile ribbon cable directly with the iron. The ribbon cable will melt almost instantly even at these low temps. Also you can rip through the silicone pad with the iron tip. If you plan on doing this more than once you may want to consider modifying a soldering iron tip to make it easier.

This is the ultimate solder-tip mod for repairing LCD displays. It’s an aluminum block with an infused high temperature rubber layer. I cut out a small rectangular piece, drilled a hole in the aluminum and just press fit a soldering iron tip that I cut the pointy tip off of. This makes it easy to apply strong downward pressure over a larger area without much risk of slipping.

Using this tip and this technique, I have been able to repair many defective LCD displays. I even repaired one that the ribbon cable had been totally ripped off the circuit board and sat in a box for over 2 years. I have also installed new heat seal ribbon cables on both the glass and the PCB using this tool.

Thanks for the great writeup! Should prove usefull…

Also, where did you get the aluminum block with the rubber?

good job

I’m trying to repair the cluster display my car

how long to push the flex to melt properly?

That would depend on the method you use. With my 2mm thick silicone rubber pad attached to the aluminum block soldering head, the pad is pre-heated because it is always attaches to the heating element. I apply strong pressure and hold it for about 5 seconds.

If you can, I would try to practice on something else before attempting an important one-time repair. Pull any old LCD out of broken electronics or even buy some scrap LCD on eBay.

thanks

I’ll try to fix it using this kit: http://www.obd2repair.com/opel-astra-pixel-ribbon-soldering-iron-ttip-w-teflon-cable-p-1591.html

if I fix it I will make a video of the process.

Hi Ben, I am looking for a cable of 125 pin, straight connectors like the pone showed in tour pictures. Do you know where I could find them ? Could you tell me which device Uses that LCD? Thanks

The heat seal cables that go from the PCB to the LCD glass are specific to each LCD. I do not believe I have ever seen a generic cable or the same cable used on different LCDs. These are not standard items.

The LCD’s I have on this page all came out of telephones. In order at the bottom of the screen…. NEC Aspire, Nortel M7310, and the last 3 are all the same from Siemens Optipoint 500

Thank you for the info. I just fixed my lcd display by using a thin silicon sheet and going over it with my solderin iron set to about 200c.It works!!

here you can buy one new product http://www.aliexpress.com/item/For-OPEL-Astra-Lcd-Display-Repair-Tools-with-T-Tip-Soldering-Iron-For-Opel-Astra-Pixel/763006286.html

Hello,I have a DJ controller wich has this problem on some LCDs,but there isn’t a adhesive connection, I have separate boards,some with LCDs,others with buttons,knobs,LEDs,all connected trough flat cables “slipped” in connectors?what should I do? disconnected and reconnect them?with the unit on or off?

thank you

It’s possible your LCD glass is connected tot he PCB circuit board using what’s called a zebra connector. That is a short rubber connection filled with tiny vertical conductive lines. When compressed between the glass and the board it will conduct only in the Z axis and does not short out between each connector. Sometimes those cause problems too. There would have to be something (usually metal or plastic box) squishing them together. It is possible to take them apart, clean with isopropyl alcohol and putting it back together. Usually it takes a few tries… and can be quite a pain but requires no special tools or soldering.

Thanks for this – I have a load of Siemens Optiplex 500 handsets with faulty LCD displays. By trimming off a piece of the keypad backing and pressing it over the connectors with a soldering iron, an almost completely broken display came back 100%!

I see you can get a soldering iron “T-Tip Head” from eBay if making one sounds like a step too far!

That “T-Tip Head” on eaby looks perfect. I may just pick one up just to try it out!

Hi everyone,

If you are looking to purchase brand new Siemens Optipoint LCD Displays please email me at Jacob@telnetworking.com, again brand new pretty good quality.

That might work on small displays like DVM etc, but have you tried it on TV’s (LCD and Plasma) as well. If the COF is bad, this will not work.

Ben – you are a star.

My blood pressure monitor suddenly started missing bars out of the digital display. It all came on quite quickly and may have been accelerated by hot weather. The supplier could only offer a replacement monitor for £75 but on finding this thread the answer presented itself. Yes the monitor contains a heat sealed ribbon tape.

I have a temperature controlled soldering iron which I set to 204 deg C (minimum setting) I made the bit out of brass with a contact edge of 7mm x 2mm. The 7mm edge was given a 20mm radius and all sharp edges were smoothed off. The silicon strip came from an old Dell keyboard. The procedure was simplicity in itself with the rounded edge enabling the bit to be rotated along its 7mm edge thus transferring the point of pressure without having to move the bit sideways.

3 slightly staggered passes across the width of the sealed contact area produced a 100% restoration of function. The resealing was made easier by the very thin silicon membrane (about 0.2mm) and the small pressure contact area and I reckon any point did not receive more than 2 seconds of pressure and heat with each pass as the bit was rocked over it. This avoided a wide area heat treatment which would probably involve longer duration and with the risk that it might partially separate when the bit was moved to the next section.

A really good repair idea which got me over my problem. Many thanks.

Peter

hi,

i think i have a problem with the ribbon cable at the Glass end. If i press it down i get rid of the lines. The LCD panel wraps around a plastic window thing and is then clamped by a metal case but i’m not sure that delivers the tension required on the Ribbon cable, where it mates with the glass. it looks loose. Is there a way i can glue it back down with electrical conductive glue that cures at room temp?

the LCD is 248×60 so its unusual and difficult to near impossible to obtain on the open market.

There is no electrically conductive glue that would not also short out your contacts. There is a 3M z-axis conductive tape that MIGHT work for you. Very hard to say without knowing a lot more about the LCD and the problem. Even then it’s still kind-of an unknown until you try it.

hi

Here is a link with photos: https://www.icloud.com/photostream/#A2JtdOXmJulGq6

Fourth photo is with some pressure applied. Last is with none and there are still some lines. So, i think i have to perform the operation you undertook and apply some pressure/tension between the LCD and the white wrap (not in shot) around frame. That tape is pricey and perhaps i should heat up the PCB and ribbon connection first and then see if there is improvement.

LCD display is to be used with CCFL, which is another problem.

I thought I should report back. I eventually got a ‘T-tip’ and a 40w soldering iron. It did improve slightly but i could not clear all the lines. I think the 248×60 which is a very fine pitched display has even smaller connections and so its more difficult to fix the line adhesion problem. Eventually, i tore through a section of the ribbon cable in what was most likely a bout of frustration. I do not think i could have fixed the line problem anyway because of the fine pitch and connecting lines.

I purchased one of these to try it out an it worked great.

http://www.ebay.com/itm/Soldering-Iron-with-T-Tip-Adapter-Teflon-strip-and-holder-for-BMW-Mercedes-Benz-/171094836060

or search for “soldering iron bmw”

Apparently BMW has problems with their LCD

Hi, I found here with UK seller

http://www.ebay.co.uk/itm/T-Tip-Soldering-Iron-40W-For-LCDs-and-Ribbons-SID-repairs-SAAB-BMW-ROVER-/281219808988?ssPageName=ADME:L:EOISSA:GB:1123

A question for my Panasonic phone display. I hope someone with experience on phone display can give me a hind or advice on the situation.

So I decided to replace my old display with a new one for my old Panasonic KXTG2431 phone. I carefully peeled the plastic ribbon (from the display unit)off from the conductive adhesive and put the new one in position.I then used a warm soldering iron carefully pressing the contacting position on where the plastic ribbon met with the conductive adhesive(just like it was before I peeled it off).I put everything back together and re-installed the battery and guess what? No display at all! No characters,just a blank screen. Thinking the new unit may not be compatible so

I put the old back in. Samething,a blank screen. So what

happened? What did I done wrong? I hope everyone can chime in and give me some advice.Thanks for your help.

This page is fantastic! It saved me tens of euros.

Here’s an impression of the result I obtained, using only a 25W soldering iron and a chunk of silicone pad from an old telephone keypad:

before

after

Wow. That IS a fantastic result. Gives me a lot of hope for my problem, fixing old Gameboys with missing horizontal lines in the display. (Vertical lines are easy, horizontal lines are thought to be irreparable)

Wow. Thanks a lot! Your article helped me to repair a screen connection. 🙂

Hello,

this methode can be used also for COF( with acf conductive adhesive tape) on LCD TV,where one side has glass and the other PCB?

Thanks

Thank you for a great tip. I didn’t have the plastic sheet you suggest but I did use a sheet of paper. Fixed one display entirely. On the other one, the (uhhh…unregulated) iron temperature had gone to about 250 degrees C and the strip melted directly.

one other tip: if your display has a rubber strip, mark its position with a marker before removal.

Thanks for the great instructions. I could repair the display of my light aircrafts autopilot (10Y old). The manufacturer would have replaced the whole unit for 1200 Eur.

I made me a tip for the soldering iron which looks quite like yours, but is aluminum only without silicone, but the working edge nicely rounded. Plus I sticked a teflon (PTFE) tape onto the ribbon cable to protect it from manual damage. The tape is very thin, it is the type plumbers use. Soldering temp set to lowest (150 C).

I should have read on all replies. The hint of Peter Norris also seems very useful with his rounded “rocking tool”.

After some days I noticed that some lines in the LCD are defective again. So contact got loose again.

I´ll give it another try with a bit more temperature and several staggered passes.

Lcd repair missing Linea dos Matriz stb tft cob cof

Hi,

LCD pad to flex PCB pad how to connect.

Also worth mentioning: old laptop screens sometimes use the same panel but different backlight. Intriguingly folks are “upcycling” old unused CCFL panels in this way with a new controller and selling them on at a profit.

The actual PCB with the special controller chip is what gets changed, to allow panel compatibility.

Used to revive missing segments of LCD on three of my 15 year old Philips Xalio 6200/6800 DECT phones. Fully functional again. Thank you so much

Don’t Understand the tool with rubber tip. Whats the rubber needed for?

Hot metal will melt the plastic in the heat seal cable and you cannot press down on all areas with pressure using metal. The rubber evens out the pressure.

Worked for me, Thank you very much. My issue was the tape to glass connection of 9 year old calculator. Wiggling the connector made it worse but one pass with a soldering iron restored it completely. Thanks again, I wouldn’t have though of this myself.

Used to successfully repair the LCD of a 25 years old Sony STR-NX1

stereo.

I have used the baking paper (folded 4 times) in place of

the silicone pad.

Thanks so much!

Does this work on COG displays

Hello Ben !

You just saved my TAN-Generator !!! 🙂

First I made it worse from one or two missing bars to nearly 90 % defect by just scratching over the contacts of the ribbon cable with a round metal peace. Then at first a contact molded with 360 deg C direct contact to soldering iron. (luckily just a small point – working under microscope)

Then I cut a 30×4 mm aluminum bar with a hole in it. Combined with Icon1-soldering station wich can go from 150 to ~450 degree celsius -> At 204 deg C.

A short piece of light paper in between: first try on the left side did not work (propably wrong angle) while the right part of cable worked perfecty. Then another try on the left making sure the aluminum bar gets full contact to the cable – reassambled and 100% working again !!!

Thank you very much from Germany ! Greetings !